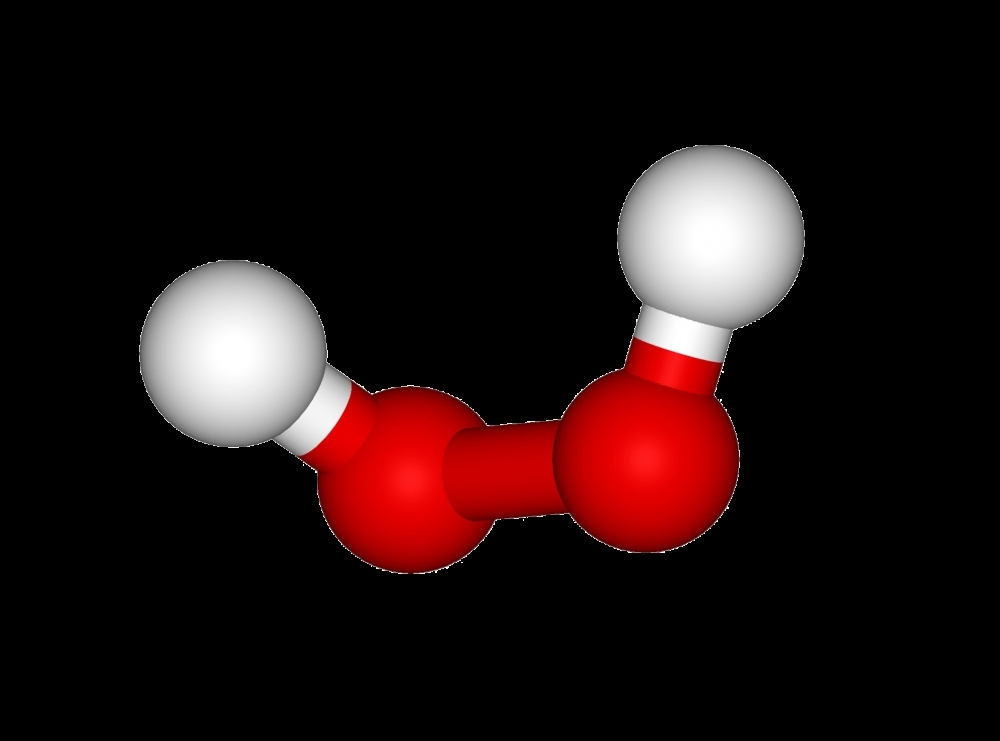

Hydrogen peroxide is used to sterilize medical equipment, to bleach fabric, pulp and paper, and whiten teeth, among other applications (image: gratispng)

Hydrogen peroxide is used to sterilize medical equipment, to bleach fabric, pulp and paper, and whiten teeth, among other applications.

Hydrogen peroxide is used to sterilize medical equipment, to bleach fabric, pulp and paper, and whiten teeth, among other applications.

Hydrogen peroxide is used to sterilize medical equipment, to bleach fabric, pulp and paper, and whiten teeth, among other applications (image: gratispng)

By Ricardo Muniz | Agência FAPESP – A study published in ACS Applied Materials & Interfaces, a journal of the American Chemical Society, describes a novel method of producing hydrogen peroxide (H2O2) without emitting carbon dioxide (CO2), one of the main greenhouse gases and one of the world’s most widely produced chemicals.

Hydrogen peroxide is used to bleach fabric, pulp and paper, and to whiten teeth. It is also used as a thruster fuel for satellite attitude control, and as a disinfectant or sterilizing agent by hospitals. Some 2 million metric tons of the compound are produced annually.

“To understand the impact of our findings, it’s important first and foremost to bear in mind the significance of H2O2 in the chemical industry and the way it’s currently produced,” said Ivo Freitas Teixeira, a professor of chemistry at the Federal University of São Carlos (UFSCar) in São Paulo State, Brazil. He has a PhD in inorganic chemistry from the University of São Paulo (USP) and was a Humboldt Fellow at the Max Planck Institute of Colloids and Interfaces in Potsdam, Germany, between 2019 and 2021.

“All this peroxide is produced by a process that involves anthraquinone [a compound derived from hydrolysis of anthracene, a toxic substance]. In this process, anthraquinone is reduced and then oxidized to make H2O2. The drawbacks of the method are the high cost of anthraquinone and the use of precious metals such as Pd [palladium], and H2 [hydrogen] as reducing agents. This hydrogen is produced by steam-methane reforming, which involves high temperatures and releases CO2, contributing to global warming,” he said.

In the study, the researchers produced peroxide from oxygen (O2) using photocatalysis to guide the process. In photocatalysis, the catalysts (substances that accelerate the chemical reaction) are activated by visible light instead of high temperature or pressure. Another advantage of their method was the use of carbon nitride as a photocatalyst. This material consists only of carbon and nitrogen, both of which are abundant in Earth’s crust, and can be activated in the visible region, which corresponds to about 45% of the solar spectrum. It is therefore probable that sunlight can be used instead of artificial lighting, making the process more cost-effective.

After testing different reaction conditions, the researchers arrived at a system with an excellent rate of H2O2 production. “We achieved O2 reduction via a photocatalytic route in which the hydrogen source was the water in the reaction medium or the sacrificial reagent, typically glycerol, a byproduct of biodiesel production,” Teixeira explained.

In this system, carbon nitride is used as a semiconductor to separate charges when bathed in light, promoting reduction and oxidation reactions. The O2 is reduced to H2O2 and the sacrificial reagent (glycerol) is oxidized. The H2O2 is obtained without the need to use H2 and hence without CO2 emissions.

“The road we had to travel in our investigation until we arrived at the results described in the published article was a long one because we discovered that at the same time as H2O2 was produced on the surface of the photocatalyst, it could also be degraded,” Teixeira said. “We had to perform several tests and keep modifying the photocatalyst in order to promote the formation of H2O2 and avoid its decomposition. Understanding the mechanism whereby H2O 2 decomposes on the surface of carbon nitride was extremely important to enable us to develop the ideal photocatalyst for this reaction.”

Teixeira leads a research team at UFSCar supported by FAPESP. He is last author of the article, which is also signed by Andrea Rogolino (University of Padua, Italy); Ingrid Silva, Nadezda Tarakina and Markus Antonietti (Max Planck Institute of Colloids and Interfaces, Germany); and Marcos da Silva and Guilherme Rocha (UFSCar).

The article “Modified poly(heptazine imides): minimizing H2O2 decomposition to maximize oxygen reduction” is at: pubs.acs.org/doi/10.1021/acsami.2c14872.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.