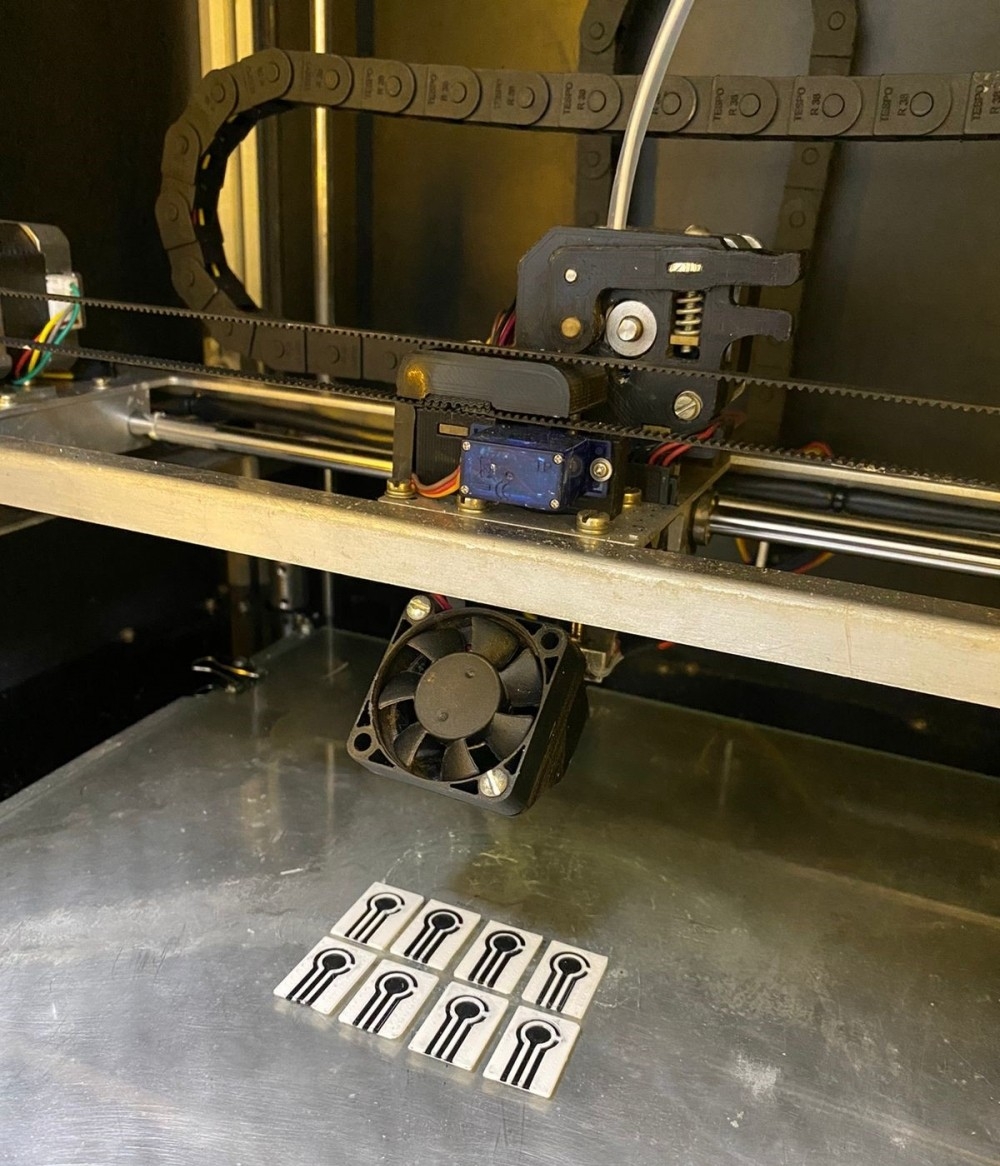

Conducted by Brazilian researchers, the study focused on the fused deposition modeling technique and was featured on the cover of Analytical Chemistry, a journal of the American Chemical Society (photo: 3D printing of sensors/credit: Bruno Campos Janegitz)

Conducted by Brazilian researchers, the study focused on the fused deposition modeling technique and was featured on the cover of Analytical Chemistry, a journal of the American Chemical Society.

Conducted by Brazilian researchers, the study focused on the fused deposition modeling technique and was featured on the cover of Analytical Chemistry, a journal of the American Chemical Society.

Conducted by Brazilian researchers, the study focused on the fused deposition modeling technique and was featured on the cover of Analytical Chemistry, a journal of the American Chemical Society (photo: 3D printing of sensors/credit: Bruno Campos Janegitz)

José Tadeu Arantes | Agência FAPESP – 3D printing, also known as additive manufacturing (AM), is a technology that combines three advantages: speed, freedom of design, and reduced waste generation.

There are various 3D printing techniques, among which fused deposition modeling (FDM) stands out for affordability, scalability, and the ability to process a wide array of materials. Applications of FDM include fabrication of several kinds of equipment used in electroanalytical laboratories, such as electrochemical cells and arrays, and more recently electrodes.

A review article signed by researchers affiliated with several Brazilian universities offers a complete protocol for the use of FDM 3D printers for the fabrication of electrochemical systems including biosensors. The article is entitled “Electrochemical (bio)sensors enabled by fused deposition modeling-based 3D printing: a guide to selecting designs, printing parameters, and post-treatment protocols”, and is featured on the cover of a recent issue of Analytical Chemistry, a journal of the American Chemical Society.

“It's a guide to everything from design and production of the structure in the initial stages of printing to the final application, including the enhancement of printed electrodes for a range of purposes,” said Bruno Campos Janegitz, a professor at the Federal University of São Carlos (UFSCar) in Araras, São Paulo State, and head of its Sensors, Nanomedicine and Nanostructured Materials Laboratory (LSNano).

The last and penultimate authors of the article are Janegitz and Rodrigo Alejandro Abarza Muñoz, a professor at the Federal University of Uberlândia (UFU). The study was supported by FAPESP under the aegis of the Thematic Project “Development of novel materials strategic for integrated analytical devices”, led by Lauro Kubota, a professor at the State University of Campinas (UNICAMP), and a postdoctoral fellowship awarded to Diego Pessoa Rocha.

With detailed descriptions and explanatory figures, the guide is intended to help users understand and solve problems associated with 3D printing. “A problem to avoid is solution leakage, which is very common in 3D printed cells, so as to produce well-sealed objects with high quality,” Janegitz said.

The LSNano lab at UFSCar Araras has used this type of 3D printing since 2018, and many projects have been based on it to date. Thanks to partnerships with groups led by Muñoz at UFU and Juliano Alves Bonacin at UNICAMP, the product range has been extended to include small items of equipment such as microfluidic devices, the study of surfaces, and the development of sensors and electrochemical biosensors for various analytical purposes, with several patent applications.

The article “Electrochemical (bio)sensors enabled by fused deposition modeling-based 3D printing: a guide to selecting designs, printing parameters, and post-treatment protocols” is at: https://pubs.acs.org/doi/10.1021/acs.analchem.1c05523.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.